Certification of Shipping Containers for Export

Written by Susan Nalevac | May 31, 2023

Every shipping container that is transported internationally must meet specific requirements that corroborate the container’s quality and structural integrity. Below, we discuss the certification of shipping containers for export.

In This Article:

What Does CSC Mean for Shipping Containers?

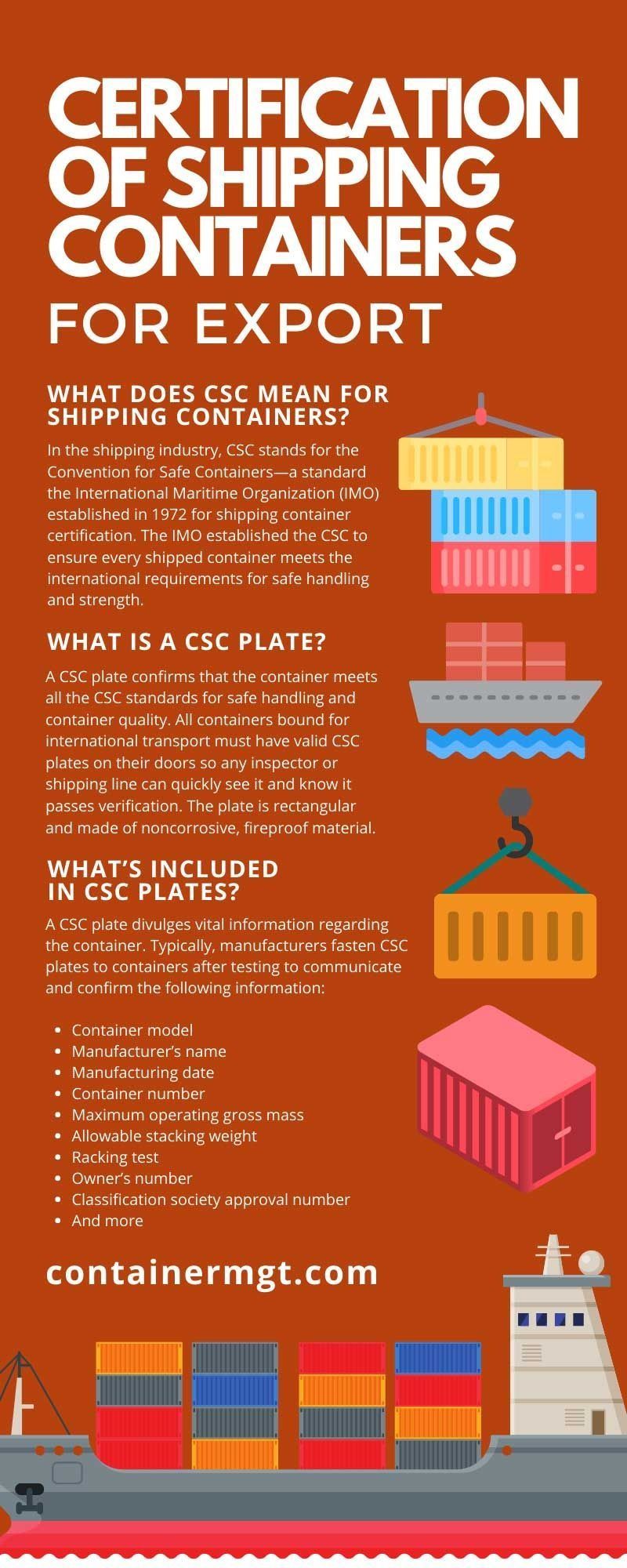

In the shipping industry, CSC stands for the Convention for Safe Containers—a standard the International Maritime Organization (IMO) established in 1972 for shipping container certification.

The IMO established the CSC to ensure that every shipped container meets the international requirements for safe handling and strength.

What Is a CSC Plate?

The Convention requires that any container used for international transport must be fitted with a valid safety approval plate (CSC Plate).

The CSC plate is fastened to every shipping container at the time of manufacture, typically to the outside of the left door.

Each CSC plate must contain a certain level of information. The words “CSC SAFETY APPROVAL” are prominent on the plate, along with the country of approval and the approval reference.

What Information is Included on a CSC Plate?

Typically, manufacturers fasten CSC plates onto containers after testing to communicate and confirm the following information:

- Container model

- Manufacturer’s name

- Manufacturing date

- Container number

- Maximum operating gross mass

- Allowable stacking weight

- Racking test

- Owner’s number

- Classification society approval number

- And more

The classification society approval number shows what inspection program approved the container and confirmed it passed said inspection.

CSC Plate Inspection Systems

There are two container inspection schemes that apply to CSC plate requirements: the Periodic Examination Scheme (PES), and the Approved Continuous Examination Program (ACEP). While they’re generally similar, they have some key differences.

PES

The Periodic Examination Scheme (PES) is the original approach for container inspection and regulation, but it’s not as common today. Small operators are the primary users of this scheme. The PES requires displaying the next examination date (NED) on the CSC plate, which must be updated after each inspection.

The first PES inspection must occur within five years of the container’s manufacture, and inspections must occur periodically afterward with no gap greater than 30 months between inspections.

ACEP

The Approved Continuous Examination Program (ACEP) is the most common inspection scheme, as it’s more thorough, consistent, and generally easier for container owners to implement. Basically, ACEP deems the container to be inspected every time it undergoes a repair—often occurring while the container is at the repair facility. If the container doesn’t undergo repairs often, then it undergoes inspection within the same intervals as the PES.

Since ACEP examinations aren’t scheduled, frequent repairs for even minor damage are necessary. Containers following the ACEP must display the scheme number on the CSC plate, often as a decal. But unlike PES containers, ACEP containers don’t have to constantly update the CSC plate with the NED.

The 7-Point Container Ocean Certification Checklist

In periodic examinations of containers for both the PES and ACEP, the inspector will conduct a seven-point survey of the container. The seven-point checklist is meant to give the inspector a thorough examination of the container inside and out, top to bottom.

While there are specific things the inspector will look for at each point, they will also generally check for signs of corrosion, dents, and other damage or degradation. The inspector will also look for signs of illegal activity, like hidden compartments.

Undercarriage

First, the inspector will examine the container undercarriage. They will check to ensure that the support beams are visible. The support or cross beams are integral to the container’s structural integrity, as they lift the floor off the ground.

Additionally, the inspector will look for signs of damage or rust in the undercarriage.

Doors

Next, the inspector will closely examine the doors, inside and out. The inspector must confirm that the locking mechanism attached to the doors is secure since containers must be able to protect their cargo while in transit. The inspector will also look for any loose bolts on the doors or signs of different color bonding material that evidence unusual repairs.

Right Side

The inspection then moves to the right side of the container—the right side when facing the doors. Again, the inspector will examine the structural beams and look for signs of noticeable repairs. The surveyor will also use a tool to tap the container walls to ensure no hidden sections or false walls exist.

Front Wall

The front wall is the wall opposite the container’s doors. First, the inspector will examine the container’s blocks and vents, ensure they’re visible, and confirm that they don’t have extensive damage. The inspector will also measure the inside of the container to ensure that the length meets CSC standards.

Left Side

The left-side inspection follows the same procedure as that of the right side—surveying for any unusual repairs, examining the structural beams, and searching for any false walls.

Floor

The inspection will confirm inside the container that the floor is uniformly flat and sufficiently distanced from the ceiling, as outlined in CSC regulations. Along the floor, the surveyor will search for damage, hidden compartments, and unusual repairs.

Ceiling/Roof

Lastly, the inspector will examine the roof. The inspector will again confirm the distance from the floor and look for hidden compartments and noticeable damage. The examination will also focus on potential leaks or cracks in the container’s ceiling.

Conclusion

We hope that our guide on the certification process of shipping containers for export has been useful and informative.

If you need CSC-certified containers, Container Management, Inc. has many quality shipping containers for sale in Indianapolis and other locations nationwide.

Browse our selection of containers or

contact our staff with any questions about our container supply.